22nd Oct 2025

AG Custom Gifts Puts Laser THICK to Work on Brick and Stone

AG Custom Gifts turns everyday materials into premium keepsakes. Owner Brian Goldberg shared with us how he uses Laser THICK film to make brick and stone work faster and cleaner. His notes read like a playbook any shop can follow for crisp edges and durable depth on porous, tricky surfaces.

“Laser THICK from IKONICS is hands down one of the best tools in our shop. Its simplicity and extreme tackiness make it perfect for sticking to even the most porous surfaces, like clay bricks.”

—Brian Goldberg, AG Custom Gifts

Brick Project: Clean, deep etch in under 15 minutes

Material: Standard clay bricks

Workflow overview: Peel, stick, laser, blast, paint, peel

Step-by-step

- Cut to size. Trim from the Laser THICK roll to match your artwork area.

- Apply to brick. Remove the liner. Press Laser THICK firmly onto the brick. Use a hard roller and your thumbs to seat the mask into pores, edges, and corners.

- Remove carrier sheet. Peel away the top carrier to reveal a blast-ready, laserable mask.

- Laser etch the mask. AG Custom Gifts runs an 80 W Trotec Speedy 400 at 100 power / 60 speed / 500 DPI, 2 passes. You should clearly see the brick through the ablated design before blasting. Treat these numbers as a starting point.

- Blast for depth. In the IKONICS cabinet, they blast at ~60 PSI with a slow, methodical sweep for a clean, deep etch.

- Paint and peel. Paint the exposed recess, let it dry, then peel Laser THICK cleanly for high contrast.

Total time (per brick):

- Laser: ~8 minutes

- Blast: ~4 minutes

- Paint and peel: ~3 minutes

Finished in under 15 minutes.

Pro tips for brick

- Surface prep: Brush off loose grit and dust. For very crumbly surfaces, a light pre-seal may help. Test first.

- Adhesion: Pressure is your friend. Roll the mask into pores. Pay extra attention to edges and corners.

- Blast technique: Keep the nozzle moving with overlapping passes for even depth.

- Paint fill: Two thin coats beat one heavy coat for sharper edges.

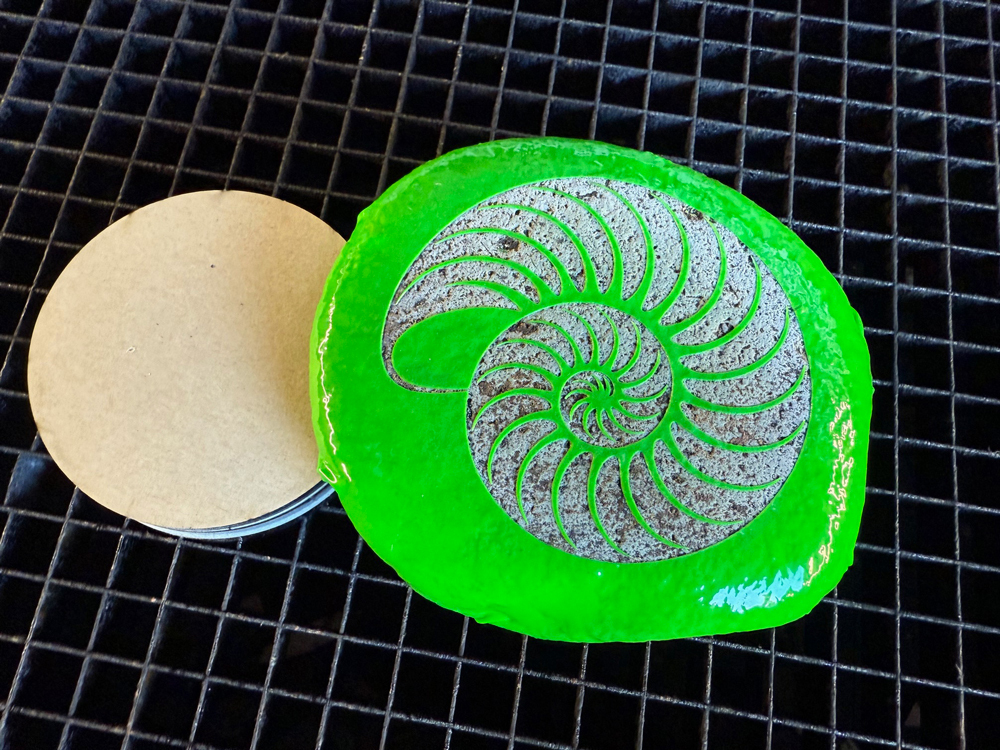

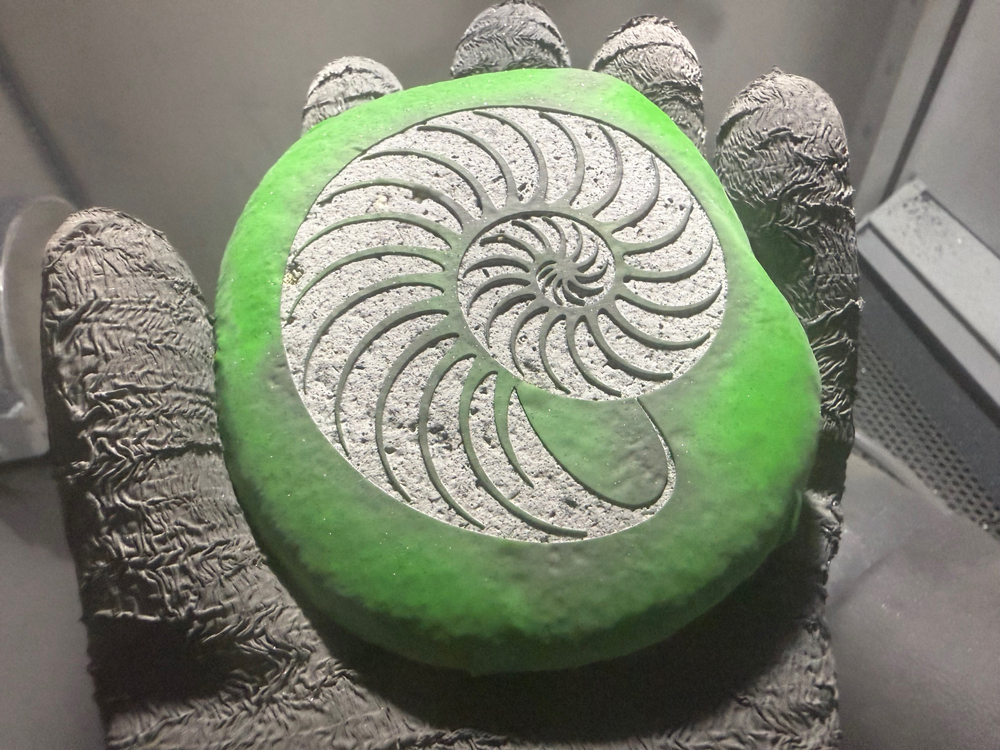

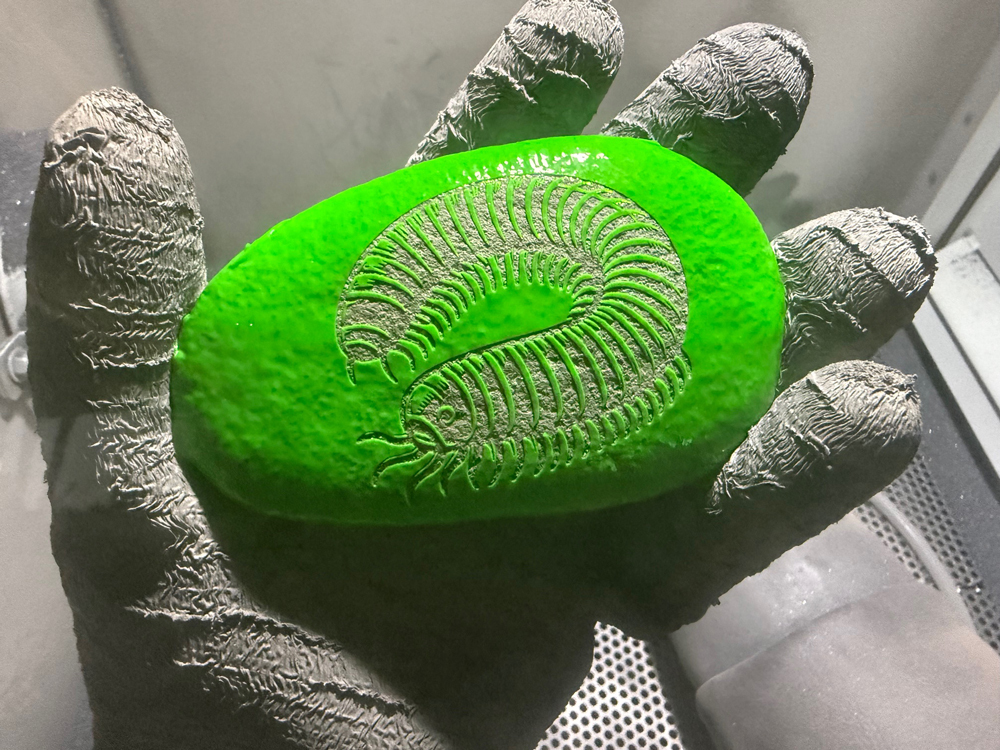

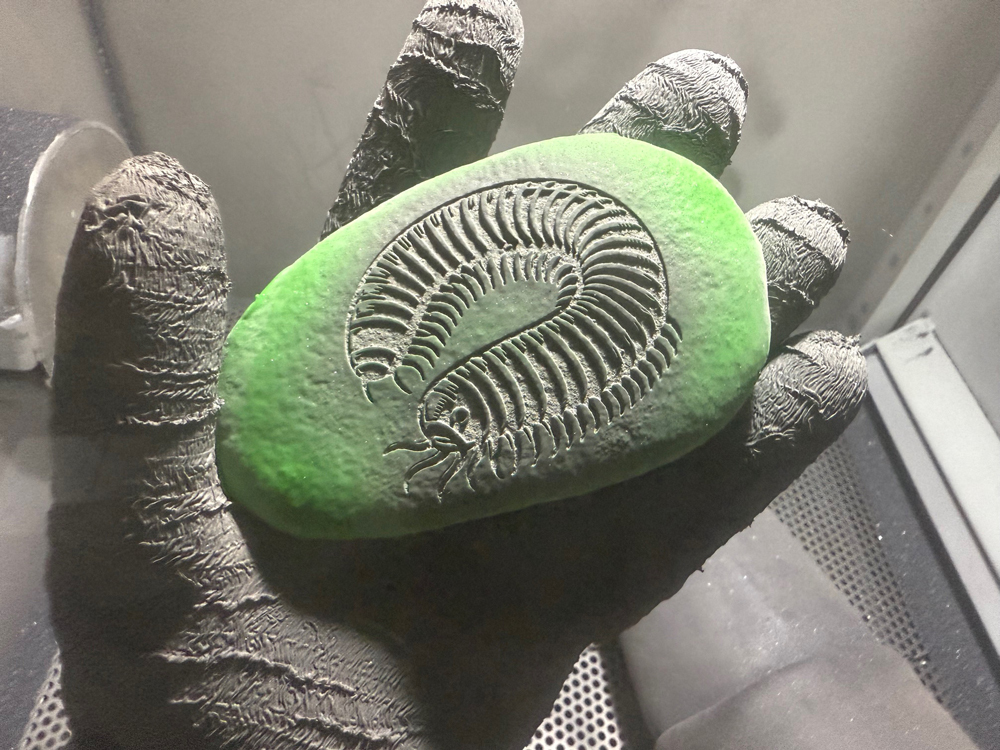

Rock Project: River stones with real character

AG Custom Gifts takes a simple approach for natural stones: peel, stick, press the mask into the pores, laser, then blast. It is a quick way to create pocket stones, garden markers, and commemorative pieces with high perceived value.

“We picked flat stones from a local riverbed and tried Ikonics Laser THICK. Peel, stick, press, laser, blast. That is it.”

—Brian Goldberg, AG Custom Gifts

What changes on stone

- Texture and curvature: Stones vary more than bricks. Seat the mask into micro-contours. Smaller designs seat more reliably on curved surfaces.

- Laser pass count: Harder stones may need extra passes to clear the mask where detail is tight. Confirm you can see the stone through the artwork before blasting.

- Blast dwell: Softer stones cut fast. Start with short dwell and adjust as needed.

Pro tips for stone

- Select smart: Flatter stones make mask seating and stand-off control easier.

- Clean first: Rinse and dry. Dust and moisture reduce adhesion.

- Optional seal: A light pre-seal can reduce paint wicking on very porous stones. Test compatibility.

- Safety and sourcing: Wear proper PPE and source stones responsibly.

Why Laser THICK shines on porous materials

- Aggressive tack: Seats into pores on brick, stone, concrete, and rough tile.

- Laserable top: Ablates cleanly for sharp, blast-ready edges.

- Blast resistant: Holds up at typical cabinet pressures for crisp sidewalls and depth.

- Clean removal: Peels off after paint without residue on most substrates.

About AG Custom Gifts

AG Custom Gifts, located in Hollister, California, creates personalized pieces that feel special and built to last. From engraved bricks for patios and memorials to natural stone keepsakes, their work pairs thoughtful design with durable production methods. They keep operations nimble, use practical fixtures and repeatable workflows, and choose materials and tools that deliver consistent, premium results.

Get started with Engraved Bricks & Stones

- Ready to add brick and stone to your offerings? Start with Laser THICK.

- Need guidance on laser settings or blast parameters? Contact us for starting points and a quick test plan.

- Looking to scale production? Ask about CrystalBlast cabinets and accessories.

Have a project to share? Send us photos and notes. Your workflow might be our next Customer Spotlight.