8th May 2017

Sandcarving vs. Laser Engraving

When it comes to personalization methods and different ways to etch or engrave, there are a lot of options in the market to choose from. Outlined below are important aspects of comparing and contrasting sandcarving, a high-quality process, versus laser engraving, a mid-to-low end of the spectrum process.

Sandcarving

- Sandcarveable materials include; glass, crystal, granite, marble, stone, ceramic, wood, stainless steel, painted or powder coated metals, plastic, acrylic and any other brittle substrate

- Sandcarving removes the material which leaves a permanent etch

- Sandcarving creates a smooth finish unlike a rough cut path with laser engraving

- Sandcarving creates sharp and clean lines with super fine detail capabilities

- Deep carving capabilities translates to a higher value and ultimate WOW factor

- Sandcarving is a quick process, 10-15 times faster compared to laser engraving

- Multi-level, three-dimensional etching capabilities also known as stage carving

- Ability to sandcarve complex compound curves including wine glasses, glass spheres and more

- Frosting and photograph etching capabilities – unique only to sandcarving

- Project size is limitless! Sandcarve any size substrate, from small trophies to large architectural doors, walls or windows

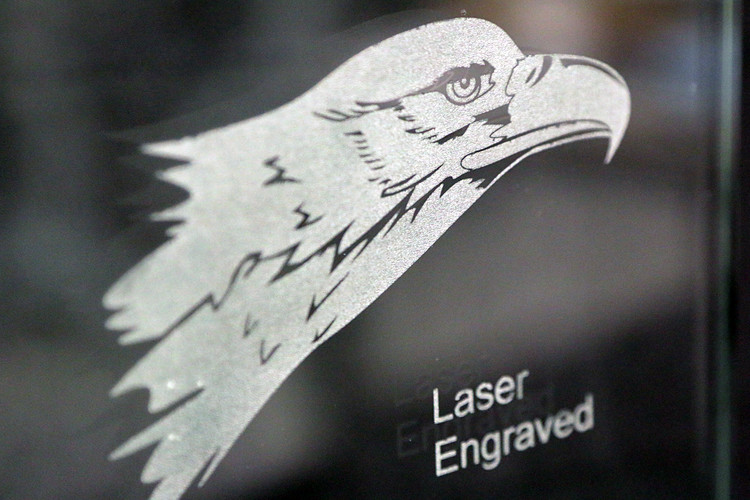

Laser Engraving

- Laser engraveable materials include; plastic, acrylic, wood, glass, crystal, ceramic, stone and other brittle substrates

- Laser engraving is microfracturing the material or substrate by directing a high intensity beam of light generated from CO2 to the surface of the substrate

- Final etch shows lines from the raster motion of the laser

- Laser engraving scratches the design into the glass and has no depth

- Lasering creates shavings to remove when finished

- This is a slower etching process compared to sandcarving

- Lasering is not capable of multi-level etching

- Lasering is not capable of etching compound curves without a jig

- The size of the substrate is restricted to the size of the laser