6th Jun 2017

The Truth about HEPA Filtration & Sandcarving

Let’s start off with what HEPA filtration stands for and a basic history! High efficiency particulate air (HEPA) originally called high-efficiency particulate absorber, is a type of air filter. Filters meeting the HEPA standard have many applications, including use in medical facilities, automobiles, aircraft and homes. The filter must satisfy certain standards of efficiency such as those set by the United States Department of Energy (DOE).

The original HEPA filter was designed in the 1940s and was used in the Manhattan Project to prevent the spread of airborne radioactive contaminants. It was commercialized in the 1950s, and the original term became a registered trademark and later a generic term for highly efficient filters.

Over the decades filters have evolved to satisfy the higher and higher demands for air quality in various high technology industries, such as aerospace, pharmaceutical drug processing, hospitals, health care, nuclear fuels, nuclear power, and integrated circuit fabrication (Wikipedia, HEPA, 2017).

Below is a simple concept about True HEPA Filtration in general, regardless of the industry. In order for any filter to meet True HEPA Filtration, one simple standard must be met:

True HEPA Filtration must have a minimum particle removal efficiency of 99.97%.

In order to achieve a 99.97% particle removal efficiency rate, the air moving through a HEPA filter must be at or below 5 CFM per square foot of filter. Any air movement that goes over 5 CFM per square foot, efficiency drops below 99.97% thus depleting the True HEPA Filtration qualification.

Looking at the sandcarving industry specifically, let’s put numbers on paper. Say a sandcarving machine has a 15 sq/ft filter, a maximum of 75 CFM of air movement qualifies this filter as true HEPA filtration. If the air movement in that machine goes above 75 CFM, this is NOT true HEPA filtration. Looking at another angle, say a sandcarving machine is running 750 CFMs, a total of 150 sq/ft of filter must be present in the sandcarving machine to qualify as true HEPA filtration! This is not really plausible or effective. Again, air movement through a HEPA filter must be at or below 5 CFM per square foot of filter. It’s that simple. Now you know the truth!

It’s important to check the numbers and do the math especially if your current sandcarving machine is coined as ‘True HEPA Filtration.’ If your facility needs to meet specific standards or if anyone on the shop floor has allergies, it’s important to know the truth and facts behind True HEPA Filtration. The equation is simple: If the CFM ÷ sq/ft of filter = 5 CFM or less then you have True HEPA Filtration. If the number is higher than 5 CFM then you do not.

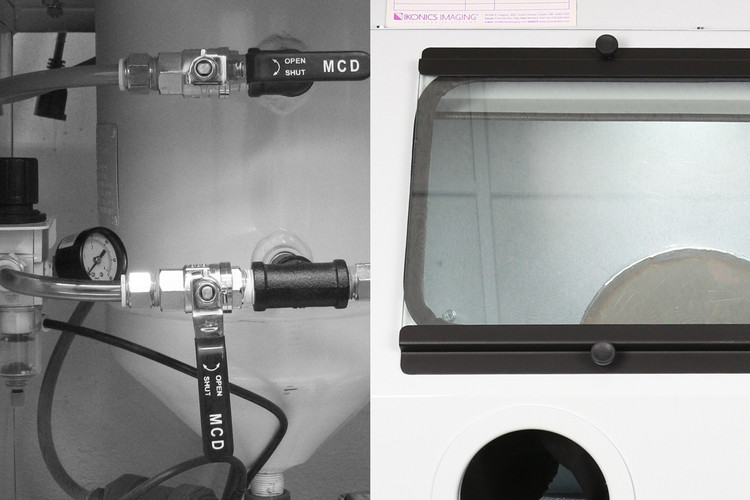

How does this exactly tie into IKONICS Imaging and the sandcarving industry? Filtration is an important topic within the industry. Although all standard CrystalBlast machines are tested within the MERV Rating System, (Minimum Efficiency Reporting Value), True HEPA Filtration is absolutely possible with the CrystalBlast Master along with any other customized machine build. IKONICS Imaging has built sandcarving machines with True HEPA Filtration which was required for a particular customer’s extreme, air-tight facility. Building a sandcarving machine with True HEPA Filtration is rare however 100% plausible with IKONICS Imaging.

Today dry filters are rated using the MERV Scale, (Minimum Efficiency Reporting Value), and all CrystalBlast machines filters have gone through extensive testing using the MERV 52.2 Testing Report to establish a single number rating for filter efficiency.

Also know that the method of filter cleaning, filter face velocity, static dust pack and filter resistance are all used when a cartridge filter is selected for use with any dust collector application.

Matching the nozzles size for abrasive delivery, the blower size for filter face velocity and the filter type are all part of the CrystalBlast machine design.

All in all, True HEPA Filtration is possible within the CrystalBlast line of sandcarving machines; however it’s not necessarily needed within the sandcarving industry. Other industries that need or require True HEPA Filtration would include; machinery cell operation, the semiconductor and aerospace industry or any other industry that requires Clean Room conditions.

Check your sandcarving numbers today! Are you satisfied with how clean your sandcarving machine is? For more information on CrystalBlast filtration, contact Wes Barton with IKONICS Imaging at (800)643-1037.

Article creation goes to Wes Barton with IKONICS Imaging and Robert Robinson with Media Blast & Abrasive. Robert Robinson draws from four decades of experience in the sandblast machinery manufacturing industry. In 1977, Robinson founded Media Blast & Abrasive, Inc., manufacturer of the CrystalBlast line of sandcarving and etching machinery and manufacturer of the largest line of abrasive blasting cabinets available on the market today.