15th Mar 2024

How Much Compressed Air Do I Need?

One of the questions that repeatedly comes up in sandcarving is, "How much compressed air do I need to run a sandcarver?" Selecting the appropriate amount of air as well as the right air compressor for your CrystalBlast Sandcarving machine is crucial to ensuring optimal performance and efficiency.

This guide delves into the specifics of compressor requirements tailored for sandcarving applications, helping you understand the key features to consider. We'll cover everything from tank capacity and pressure requirements to durability and maintenance needs, ensuring you make an informed decision that enhances your sandcarving projects.

Choosing An Air Compressor

The following information for how to choose the right air compressor comes from Robert Robinson at MediaBlast & Abrasive, Inc. and is based on operating a 3/32" nozzle machine at normal pressures for sandcarving. Operation using a 120 volt single phase air compressor is not realistic, because holding the 90 to 100 psi pressure for machine controls is not possible.

The two photos above show important pieces of the puzzle so you can answer the question of how much compressed air is needed with accurate, easy-to-understand specifications, as well as a cost for the compressor.

Below are some features to look for in an air compressor:

- Vertical Tank: Takes up less space

- Tank Capacity: 60-gallon capacity

- ASME Coded Tank: This means you can now have employees working in the area; non-ASME Coded Tanks are fine for your garage but are not allowed for shops that have paid employees and Workman's Comp. Insurance

- Pressure: This tank has a maximum pressure of 135 psi; you want your Sandcarving machine controls always operating with a minimum of 90 psi, so 135 psi allows you a 45 psi cushion; some models go to 150 psi, but they normally have a duty cycle less than 100%

- Cast Iron Pump: Durable; industrial grade quality

- 100% Duty Cycle: Continuous duty rating; extended operating cycles

- 14 CFM @ 90 PSI: Never be confused by simple displacement with 0-pressure in the tank (hard to pump up a tire with no pressure inside the tank); uses less than six CFM during sandcarving with 6 CFM leaving the tank and the ability to place 14 CFM back inside the tank; this means the air compressor gets to cycle on and off allowing it to cool, which always makes them last longer

- Double the CFM: Over double the CFM required to operate a 3/32" standard nozzle size; allows you to wear the nozzle and continue to operate; the larger the nozzle the more volume it requires to maintain sandcarving pressure; because 1/8" nozzle uses 10 cfm at sandcarving pressure you can also occasionally use the larger size (NOTE: if you are always going to use the 1/8" nozzle then we advise a larger capacity air compressor and possibly more dust collector or semi-automatic cleaning cycle)

- Oil Gauge: Oil gauge with visible sight glass

- Switch: Electrical switch supplied

When selecting an air compressor, consider these factors:

- Duty Cycle: This refers to the proportion of time, in ten-minute increments, that the compressor can run before needing to cool down. For example, a 50% duty cycle means the compressor runs for 5 minutes and rests for 5 minutes. Rotary screw compressors typically have longer duty cycles compared to reciprocating ones, with some piston compressors offering 100% duty cycles due to slower speeds that produce cooler air.

- Air Volume (CFM): It's important to focus on the CFM (cubic feet per minute) a compressor produces rather than its horsepower (HP). Historically, a compressor's HP was expected to produce four times its HP in CFM, but modern compressors, especially smaller ones, often yield less.

- Air Pressure (PSI): Ensure the compressor can maintain a pressure higher than what your sandblasting cabinet requires. If your blasting operations need 80 psi, a compressor that can operate between 95-125 psi is suitable as long as it provides adequate CFM.

- Power Source: The available electrical power can be a limiting factor. Standard outlets might only support compressors up to 2 HP, insufficient for more than minimal blasting tasks.

Always consider potential future needs and losses from the compressor's placement when sizing, and multiply your total CFM requirement by 1.5 to ensure sufficient air supply. For smaller cabinets, base your calculations on the CFM at 90 to 100 psi rather than displacement figures, which don't account for decreasing performance at higher tank pressures.

Robert Robinson draws from four decades of experience in the sandblast machinery manufacturing industry. In 1977, Robinson founded Media Blast & Abrasive, Inc., manufacturer of the CrystalBlast line of sandcarving and etching machinery. Media Blast & Abrasive partners with IKONICS Imaging to offer the sandcarving industry a complete line of machinery, photoresist, and expertise.

How To Determine Pressure Blast CFM Consumption for Sandcarving

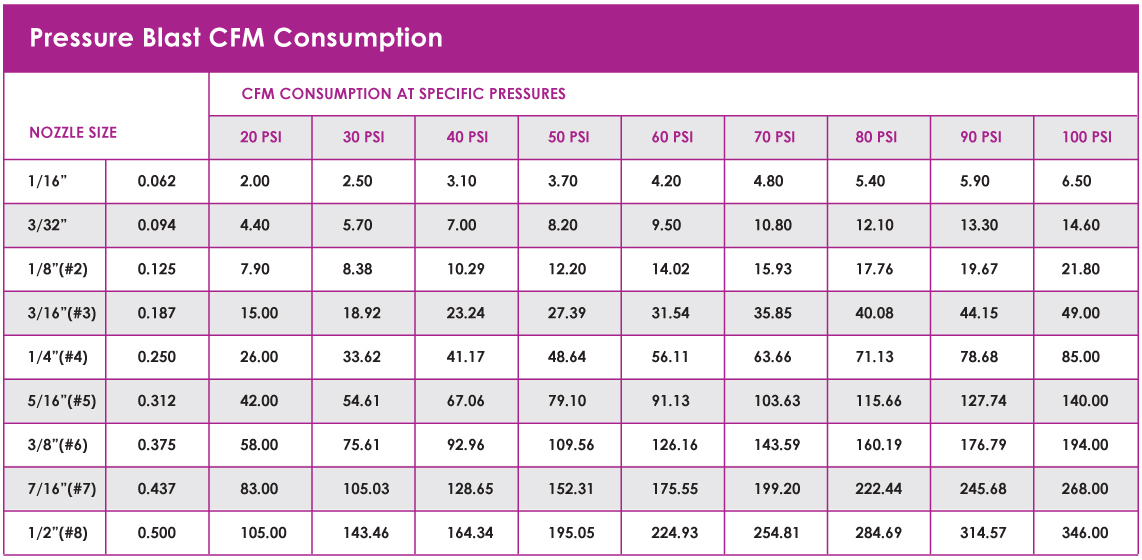

This chart shows the standard CFM consumption at specific pressures. Click here to download and print this pdf chart.

At IKONICS Imaging, we are committed to providing you with the best tools and resources to make your sandcarving projects a success. For more tips, tutorials, and information, please visit our sandcarving blog and explore our range of high-quality sandcarving products on our website.

If you have any additional questions about how to select the right air compressor and compressed air for your specific shop, please contact IKONICS Imaging today.