21st Jul 2023

How To Choose Abrasive For Sandcarving

If you are just getting started with sandcarving all the different options can feel overwhelming. We are here to help you choose the right sandcarving equipment, sandcarving film, and sandcarving accessories for your specific shop so you can be successful.

In this Q&A Darin Jones, aka Dr. Fine Grit, answers common questions we get about our two sandcarving abrasives - Silicon Carbide and Aluminum Oxide. Find out what the differences are and how to know which one to choose for your next sandcarving project.

Silicon Carbide vs. Aluminum Oxide - Choose Your Sandcarving Abrasive

Whether you prefer to read your information or watch it, we have you covered. Keep scrolling to read more about choosing your next sandcarving abrasive or head to our latest YouTube video, Q&A: Silicon Carbide vs. Aluminum Oxide, to watch Darin explain the differences.

What types of abrasive does IKONICS Imaging offer?

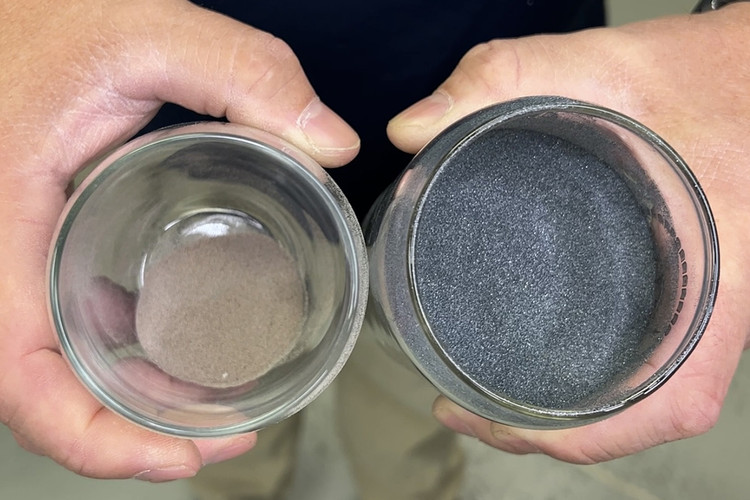

IKONICS Imaging offers two type of grits. We have aluminum oxide and silicon carbide. Both come in 150, 180 and 220 grit size. You can tell the difference between the two abrasives by color. Silicon Carbide is a dark gray/blackish color and Aluminum Oxide light brown.

Why would someone choose Silicon Carbide over Aluminum Oxide?

The reason why you would choose Silicon Carbide grit versus Aluminum Oxide is the carbide abrasive never dulls, it re-sharpens itself as you use it. It's also cleaner. Aluminum Oxide abrasive creates static electricity and sticks to your part, where Silicon Carbide falls off your part as you are sandcarving and gets reclaimed. The carbide abrasive is also harder and sharper so it's going to carve your product quicker.

Are there any differences between the two when you're sandcarving?

When sandcarving with Aluminum Oxide you won't be able to easily see where you are sandcarving when the air hits your part, however with Silicon Carbide when the carbide hits the glass (or metal or marble or whatever substrate you are carving), it creates a spark. It's not a harmful spark, but it's like a flashlight effect so you know where you're sandcarving at all times. Sandcarving artists like it because they can do their shape carving and detail work a lot quicker and more efficient.

How do you tell when the abrasive is bad?

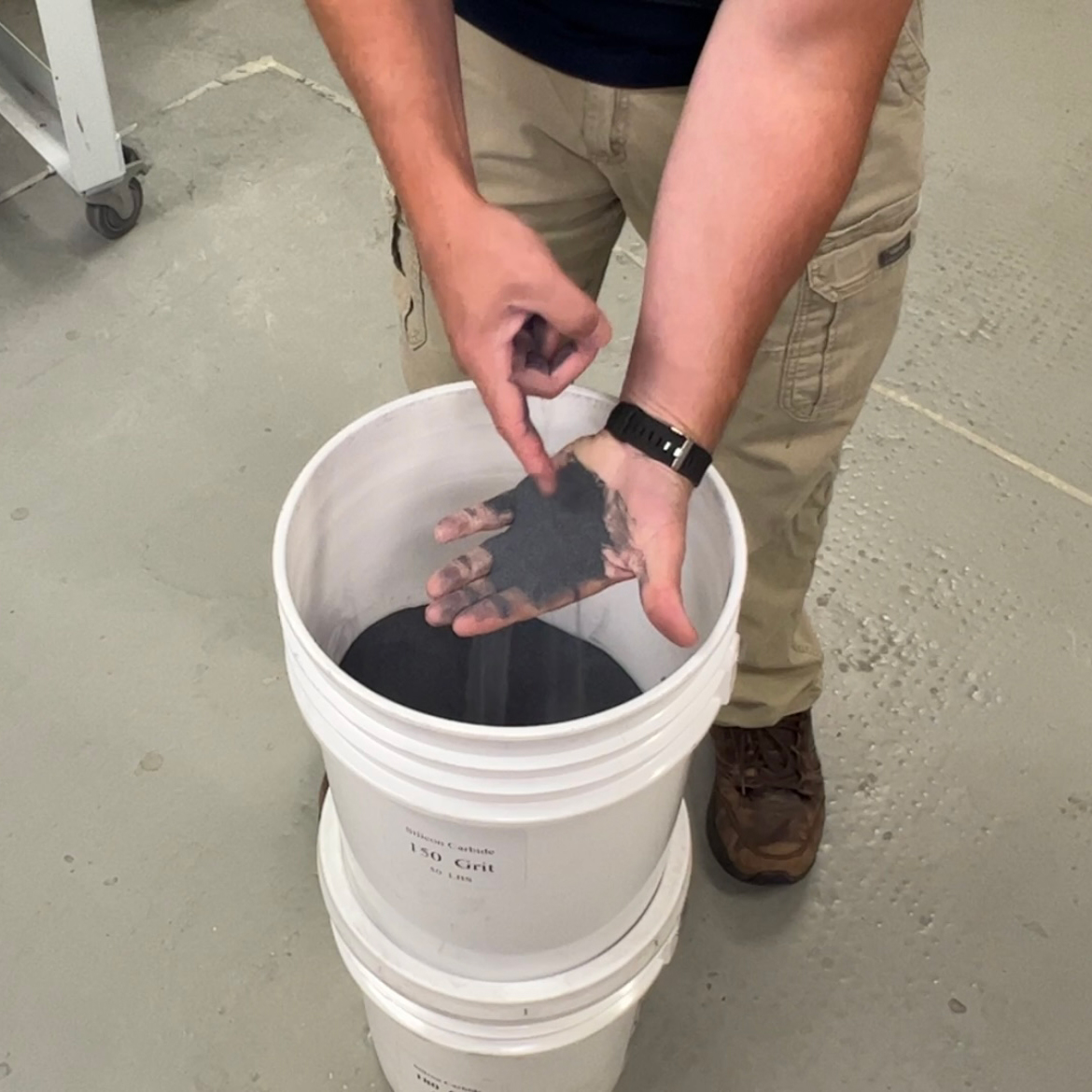

The way to tell if the grit is good is you want to pour some in your hand. Our abrasives are not harmful and there are no chemicals. Just put the abrasive in your hand and clench it. You shouldn't see any shapes or what I all little sugar cubes. If you see shapes or sugar cubes that is a sign that the abrasive is not dry. The other thing you can do too is take a cup, poke a hole in the bottom and then put the abrasive in the cup. If the grit doesn't fall freely through the hole then the grit is not good quality. If you are using a low quality grit or your grit is damp it can clog your CrystalBlast sandcarving machine.

Can all of our CrystalBlast sandcarvers handle both grits?

Our sandcarving machines can handle either abrasive. If you prefer the Aluminum Oxide that's fine in our machines. It will recycle many times like the carbide would. I do recommend the Silicon Carbide just because it's going to last longer in the machine over the lifetime so you get your money's worth.

As far as the lifespan between Silicon Carbide and Aluminum Oxide I usually say the carbide lasts about two to three times longer than the oxide. Because it self sharpens it stays harder for a longer period and stays sharp at all times.

When would you choose 150 versus 180 versus 220 grit size?

It's similar to choosing sandpaper at the hardware store. 150 grit will remove the surface faster and 220 would be better for a fine surface. It's the same with choosing grit size for sandcarving. 150 is going to carve quicker and you will get a coarser surface, whereas with the 220 you get a finer, smoother surface. 150 will again carve quicker than a 220 because the 150 is heavier.

The other reason you would use 150 is for a textured surface. So if you're doing a lot of color filling projects like wine bottles you definitely want to use the 150 grit. On the other hand if you're doing a lot of halftone images then you want to use 220 because those little sand particles are going to work its way into the fine detail faster.

In general I recommend 180 for most people because it's right in the middle between a fine grit and a coarse grit so you can do a variety of items with 180.

If you have any additional questions about choosing the right abrasive for your next sandcarving project, please contact IKONICS Imaging today. Our tech support team is here to help.